BIM Software for Precast Concrete Producers

A model-based workflow with Tekla software minimizes costly surprises and waste, improves efficiency and quality, and ensures that the correct, error-free elements are delivered in the right place at the time.

With Tekla you can work with any structure regardless of material, size or complexity. Because the software integrates design and detailing with fabrication and project management, you can streamline the entire precast workflow from bidding to delivery. Tekla allows accurate estimation and thus winning more bids and increasing profits. You can detail any precast concrete structure, improve document production, plan and control fabrication and find potential problems with your constructible model.

The software interfaces with production management systems (ERP) and precast and rebar production machinery (CAD-CAM). The information-rich models allow you to coordinate design, fabrication and site operations and ensure delivery according to the schedule.

With Tekla you can

- Reduce waste and total cost

- Estimate accurately and manage risk when bidding

- Avoid detailing and fabrication errors and minimize the need for rework

- Link with production machinery, transfer information efficiently and avoid human errors

- Enhance communication and coordination using the model

Precast concrete estimation and bidding

BIM Software for Successful Precast Concrete Projects

When you work on a precast concrete construction project, estimation and bidding are among the most important phases of the process. Model-based working helps you manage risk, win more bids and grow profits.

With Tekla software you can quickly create conceptual models and generate accurate quantities for estimation, visualize structural solutions that meet your manufacturing and company standards and then present the optimal solution to your client.

Precise quantity take off reduces risks when bidding and model-based working helps you ensure that project can be built efficiently in terms of time, cost and safety.

Easy tools for fast modeling

Effective reference handling and compatibility

Accurate quantities fast from the model

Communicate your precast concept

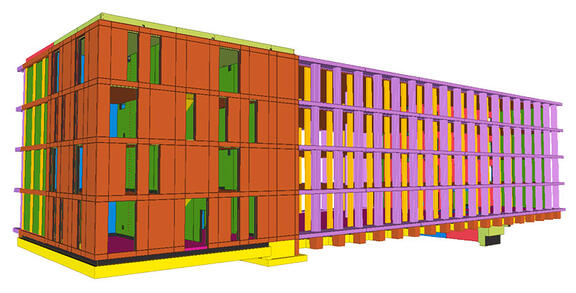

Precast concrete detailing

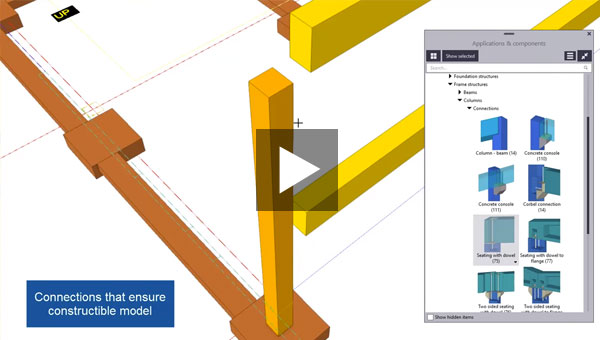

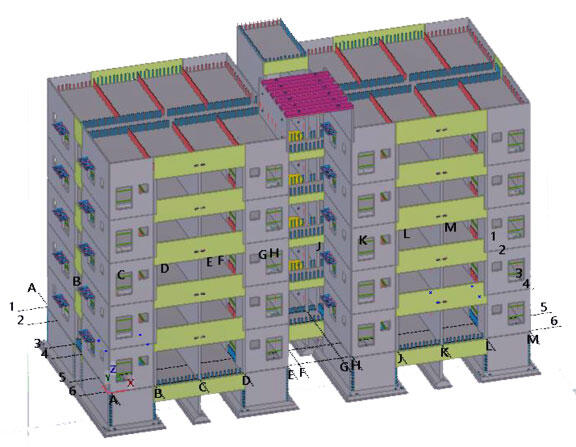

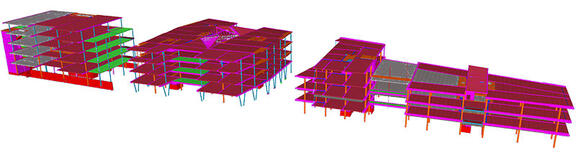

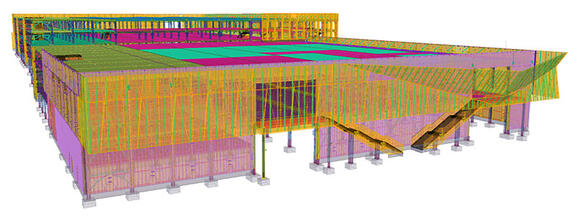

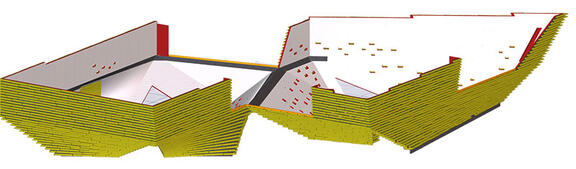

BIM Software for accurate, error-free precast concrete detailing

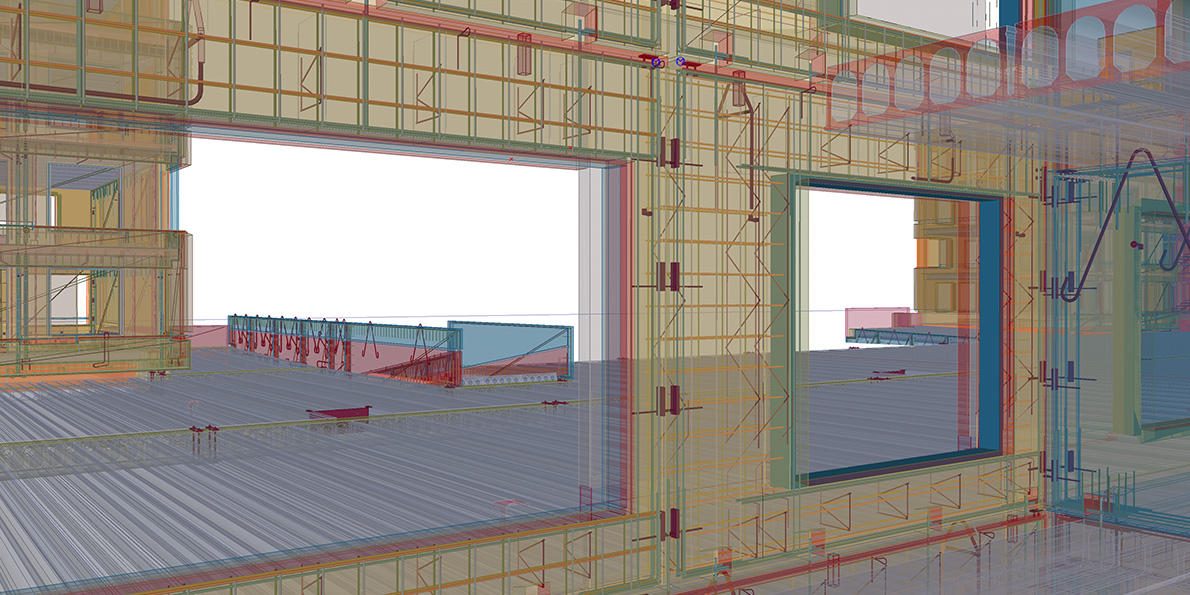

Errors, conflicting detailing documents and inefficient information transfer lead to wasting material and resources and costly rework in the detailing department, factory and on site. When you detail with Tekla Structures you can find clashes and potential problems already at the office with your building information model, not on site.

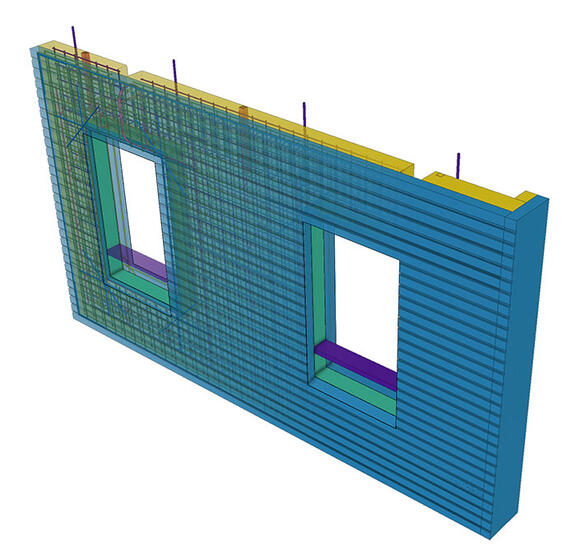

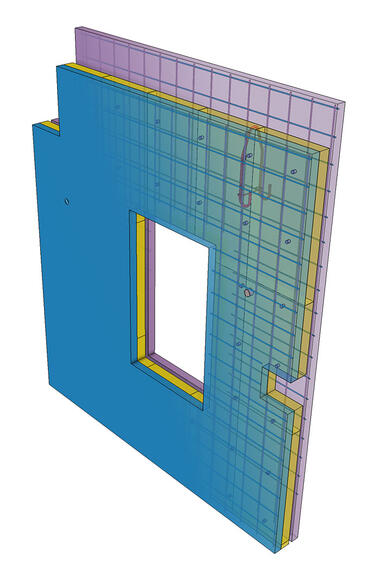

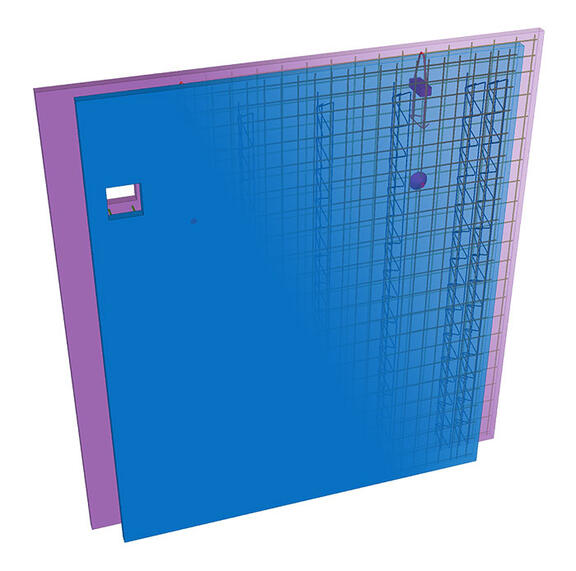

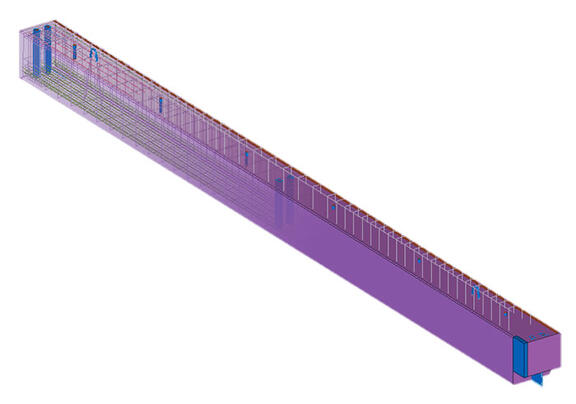

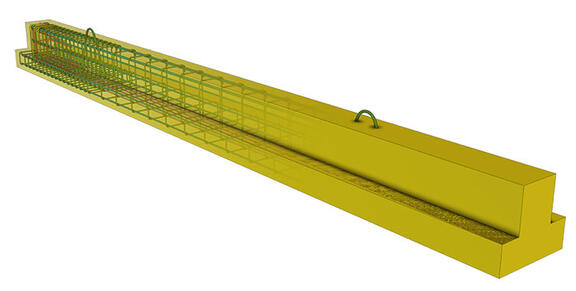

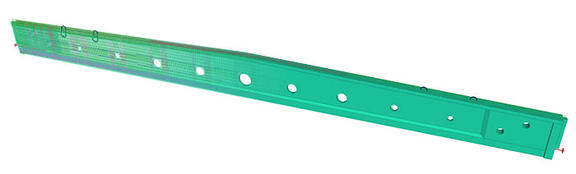

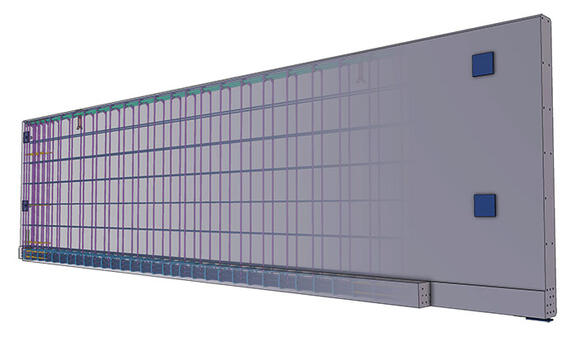

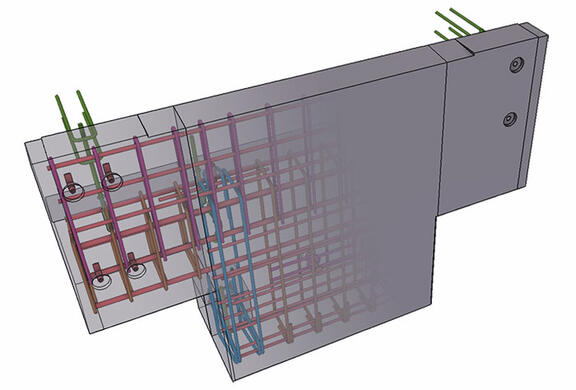

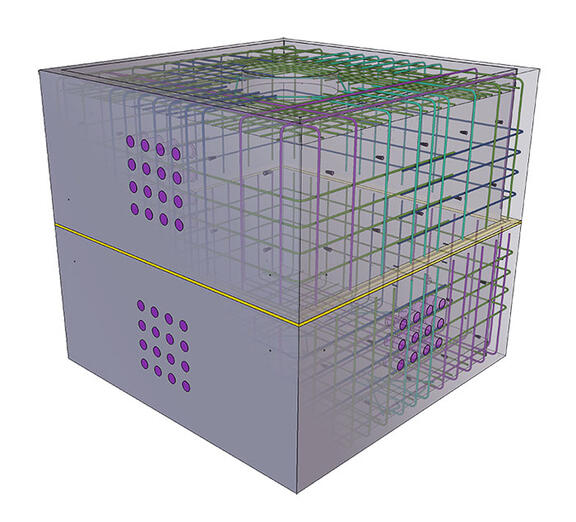

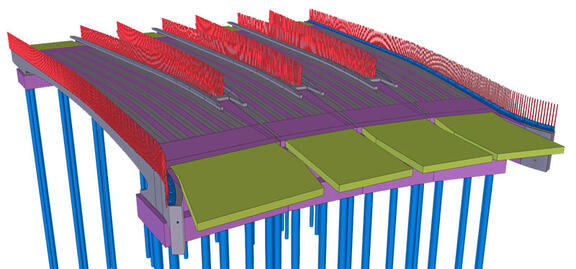

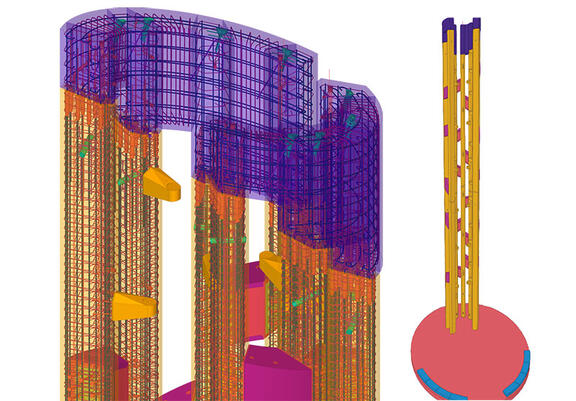

The software allows you to model all types of precast structures complete with connections, concrete embeds and even the most complex rebar. Tekla works with all materials regardless of the size or complexity of your project.

The constructible Tekla model includes all the information for generating drawings, reports and fabrication data. As project changes in the model can be automatically updated to all documents, the information stays consistent. This prevents human errors and reduces manual work.

Accurate 3D information helps everybody understand the design intent and improves collaboration between design, factory and site.

Work inside a virtual building

Error free, up-to-date drawings and fabrication data directly from the model

Customize Tekla Structures to meet your needs

Work on the same model regardless of team members' location

With Tekla you can

- Detail any structure regardless of material, size or complexity.

- Find clashes and avoid errors in drawings and fabrication data.

- Extract perfectly associative drawings and reports from the model.

- Manage changes easily.

- Standardize and streamline your work.

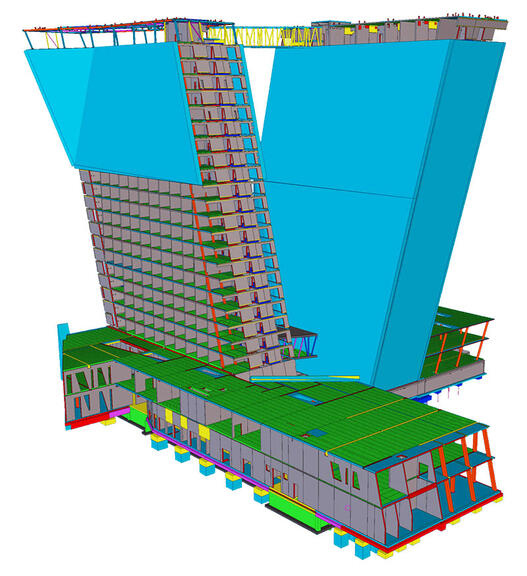

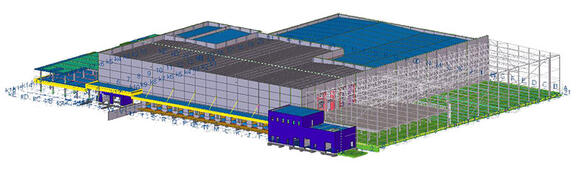

Fabrication

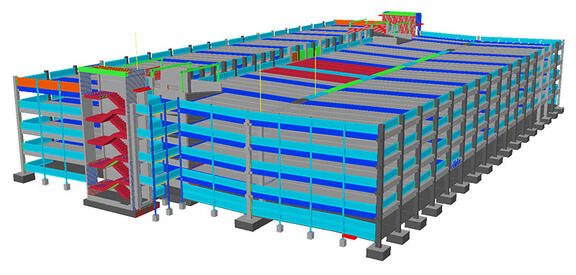

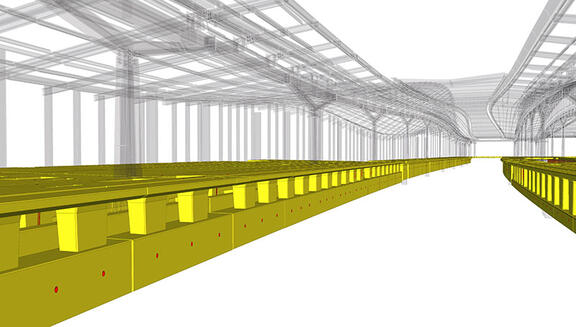

Easy access to accurate data for planning and controlling precast fabrication

Inefficient transfer of fabrication data, incorrect or inaccurate documents and insufficient communication between project members lead to waste, unnecessary work and affect production quality. Model-based workflows increase productivity, enhance information transfer, prevent human errors and help staying in schedule.

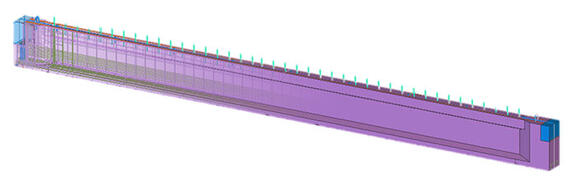

The accurate Tekla models offer easy access to quantities, geometry and material information for planning and controlling fabrication. The software integrates with precast concrete and rebar production machinery and it offers open, readable data for production management. When the constructible Tekla model is used as the source of information, you always have the same consistent data to utilize for material reports, fabrication drawings and data files created for CAM software.

Sequence and status information in the as-built models make planning and monitoring production easier and ensure reliable delivery according the schedule. With easy-to-use mobile solutions, everybody can enjoy the visual model information. This allows fabrication personnel quickly understand the design intent and improves both the efficiency and quality of the production.

Integrate to machinery; interface with production management software

The information you need at hand

Mobile solutions bring visual model information to the shop floor

With Tekla you can

- Link BIM to production automation systems (CAD-CAM).

- Get quantities for scheduling and procurement quickly.

- Exchange data with production management solutions.

- Understand the design intent easily.

- Utilize model data to plan production.

- Monitor progress and ensure delivery according to schedule.

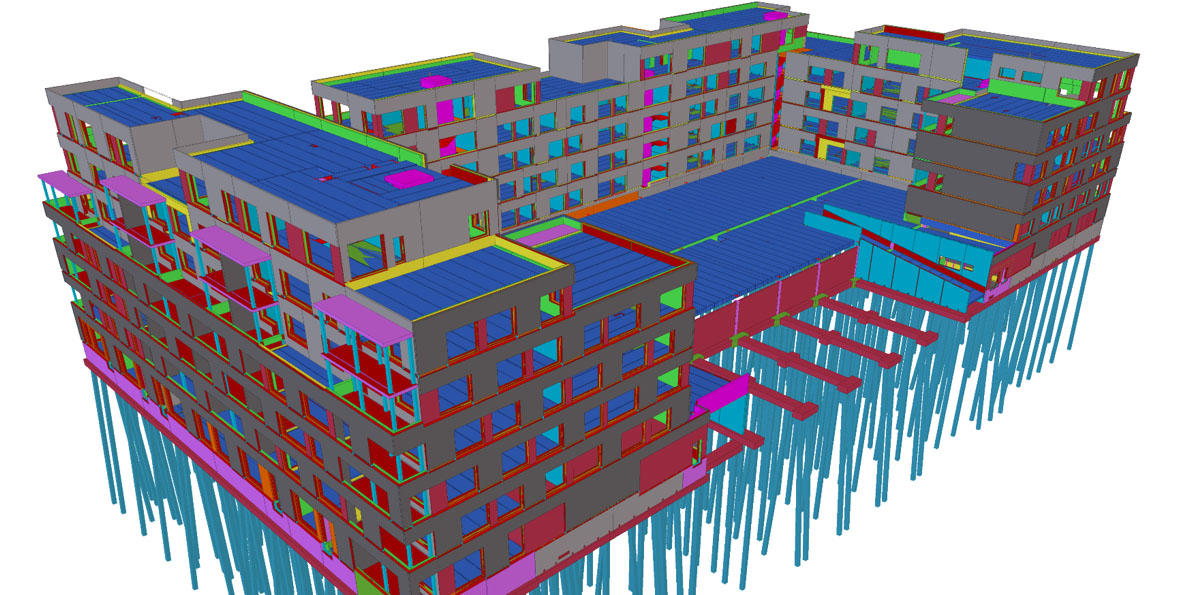

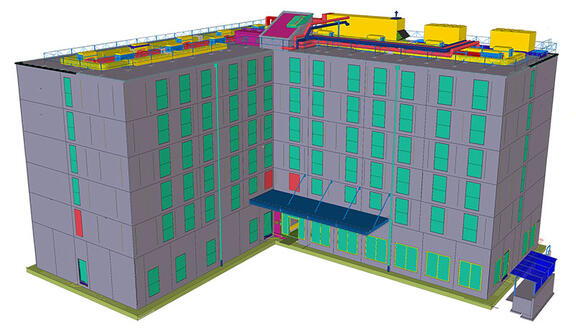

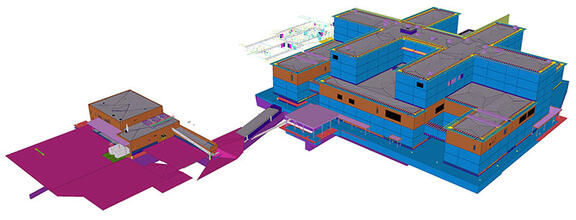

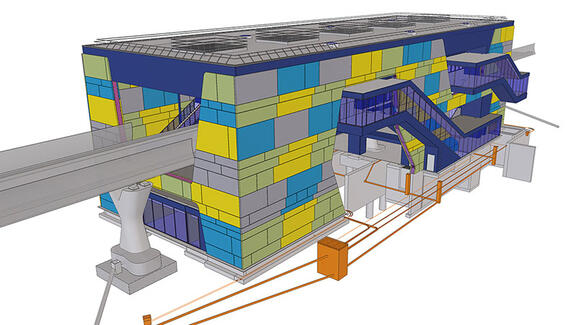

Planning and coordination of precast concrete

BIM software for reliable precast delivery and smooth erection phase

Delayed element delivery can set a site in a standstill and flawed products can create costly rework, wasting both time and resources. A BIM-based workflow and the information in Tekla models helps you ensure that the correct elements are delivered error-free to the right place at the right time.

Model-based workflows with Tekla help project planning, following up the progress and keeping all parties of the supply chain well informed at all the stages of the project. Utilizing the status information in the model is a clear and effective way to coordinate the project and ensure its progress according to the schedule.

Information rich models enable better project understanding, potential problems become easier to identify and because everybody stays informed also safety is improved. Adaption to the project changes becomes flexible when everybody has the same view of the project situation. Reporting to the client is straightforward with the 3D visualizations.

With easy-to-use mobile solutions, the model information benefits everybody regardless of location and computer skills.

Plan erection sequence and ensure safe execution

Coordinate projects and ensure progress according to the schedule

Bring clear model information to the project meetings and site

With Tekla you can

- Plan the erection phase and achieve safe execution.

- Add sequence and status information to model objects and visualize.

- Monitor the process and ensure its progress according to the schedule.

- Enhance the information flow between all project parties.

- Increase the efficiency of the project meetings.

- Solve possible issues early and ensure a smooth erection phase.

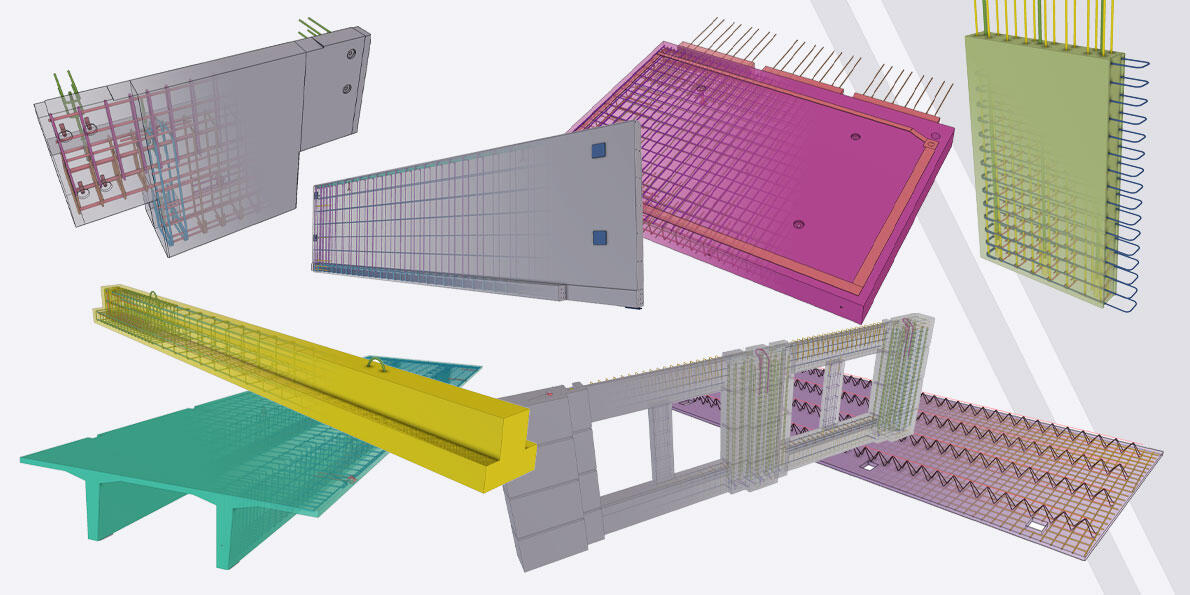

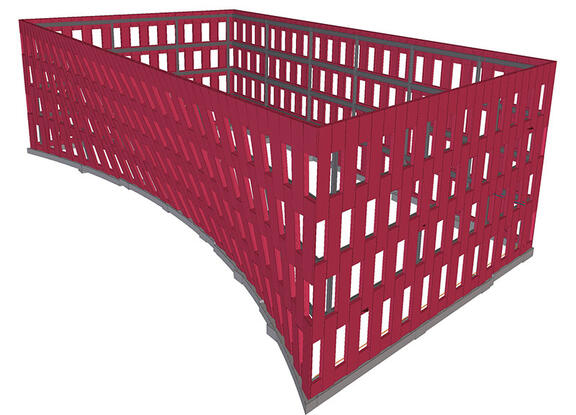

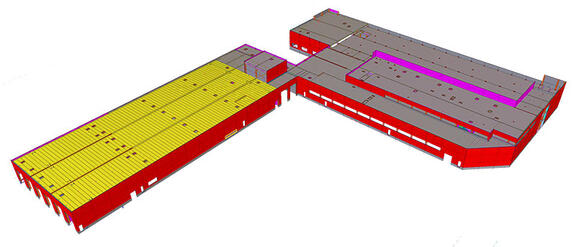

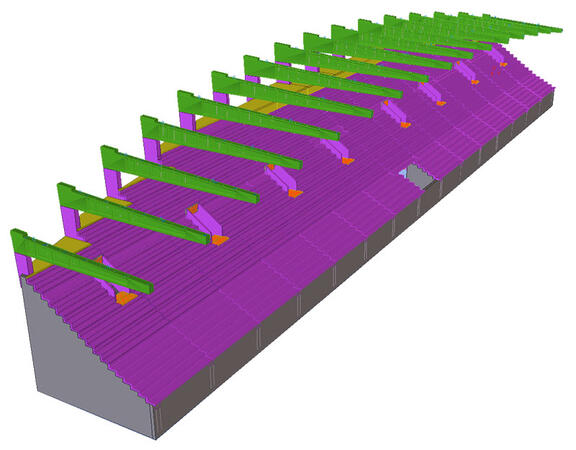

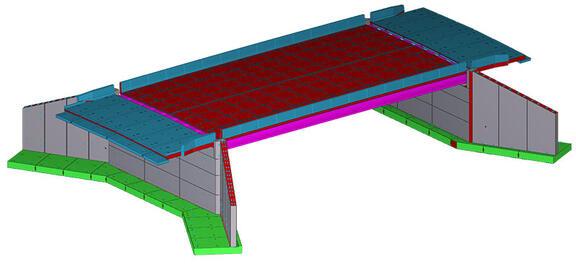

Any precast product

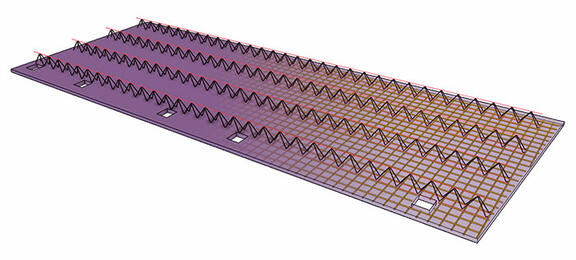

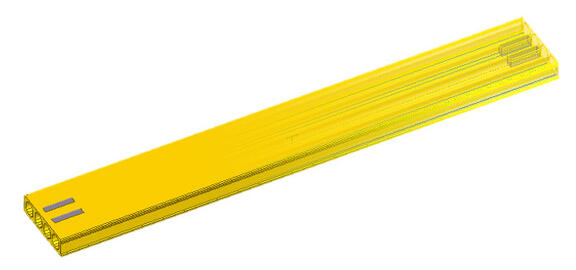

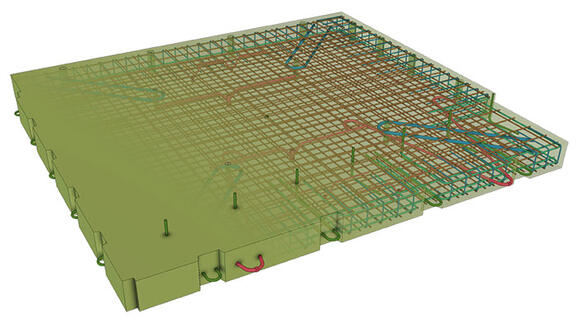

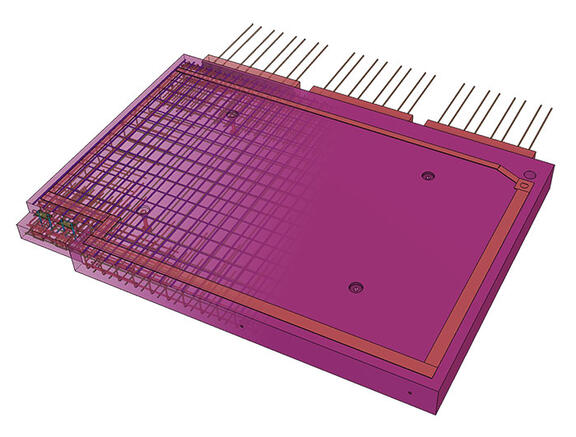

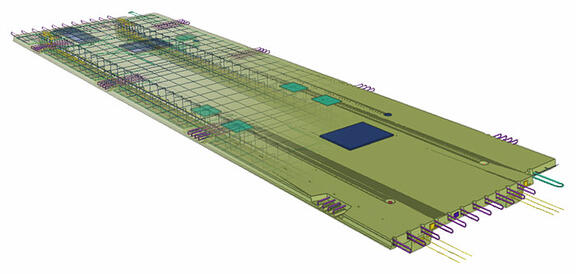

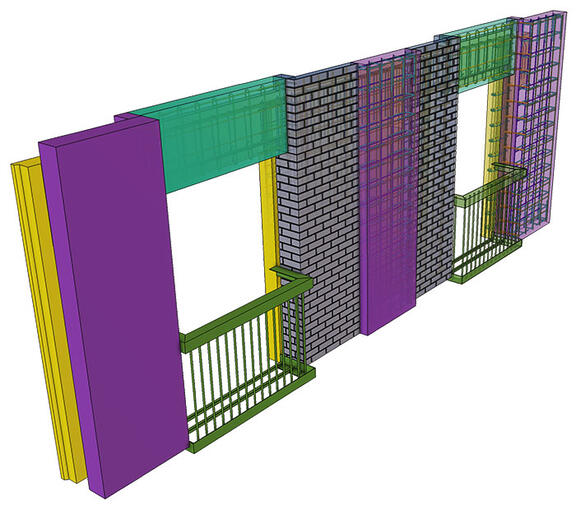

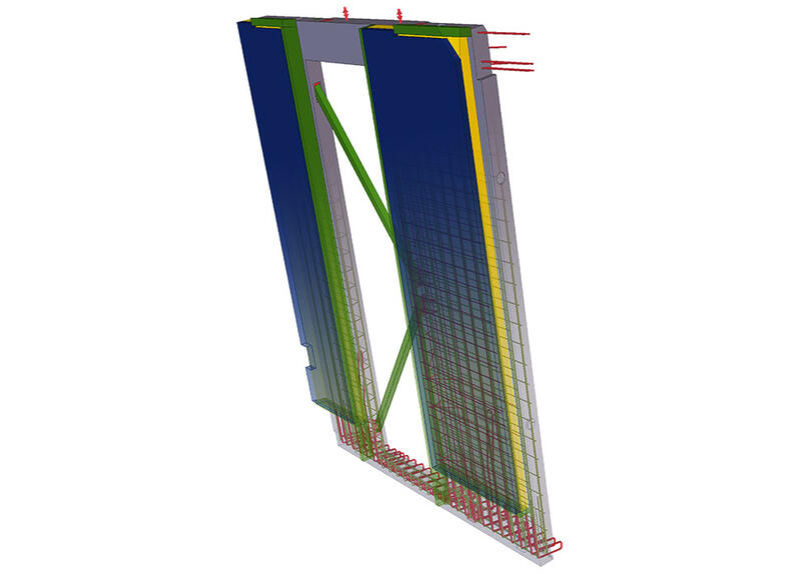

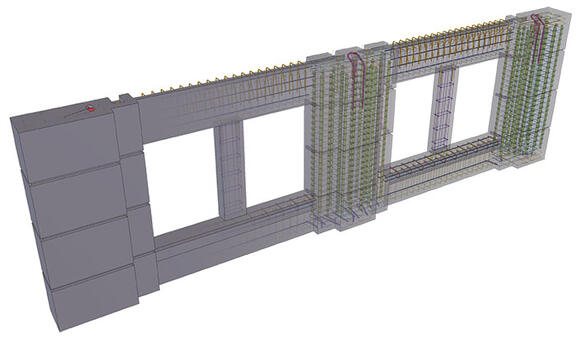

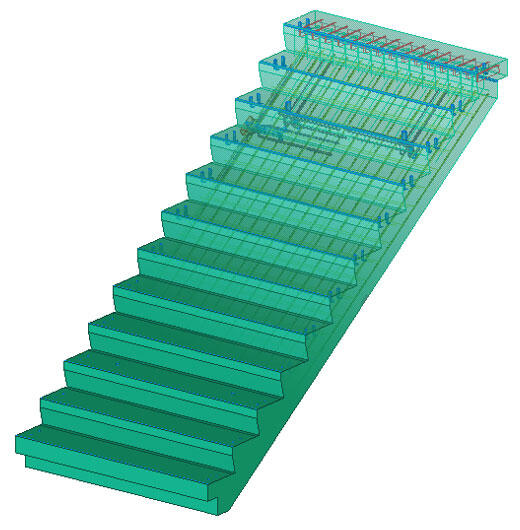

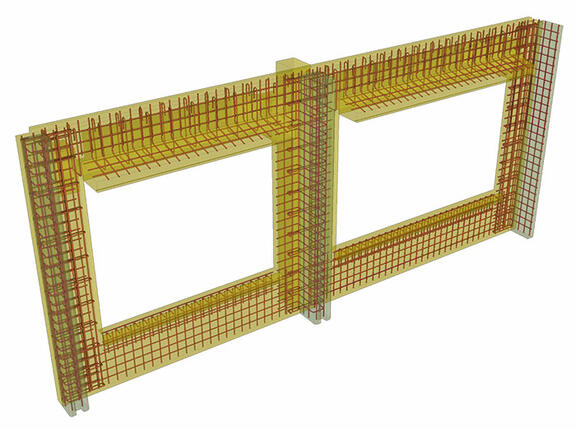

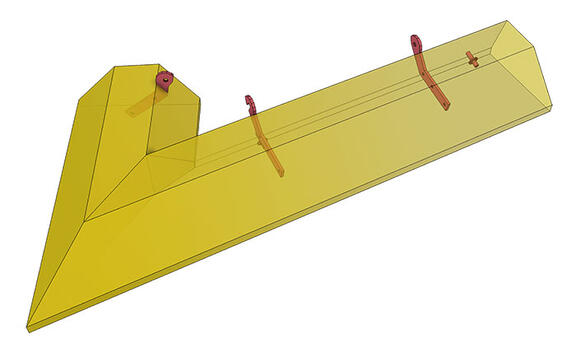

Tekla Structures is ideal for modeling a wide variety of precast products. Here are some examples of element types created in Tekla Structures:

Slabs

Walls

Frame elements

Special function

With Tekla you can

- Detail any structure regardless of material, size or complexity.

- Find clashes and avoid errors in drawings and fabrication data.

- Extract perfectly associative drawings, reports and production data from the model.

- Manage changes efficiently.

- Standardize and streamline your work.

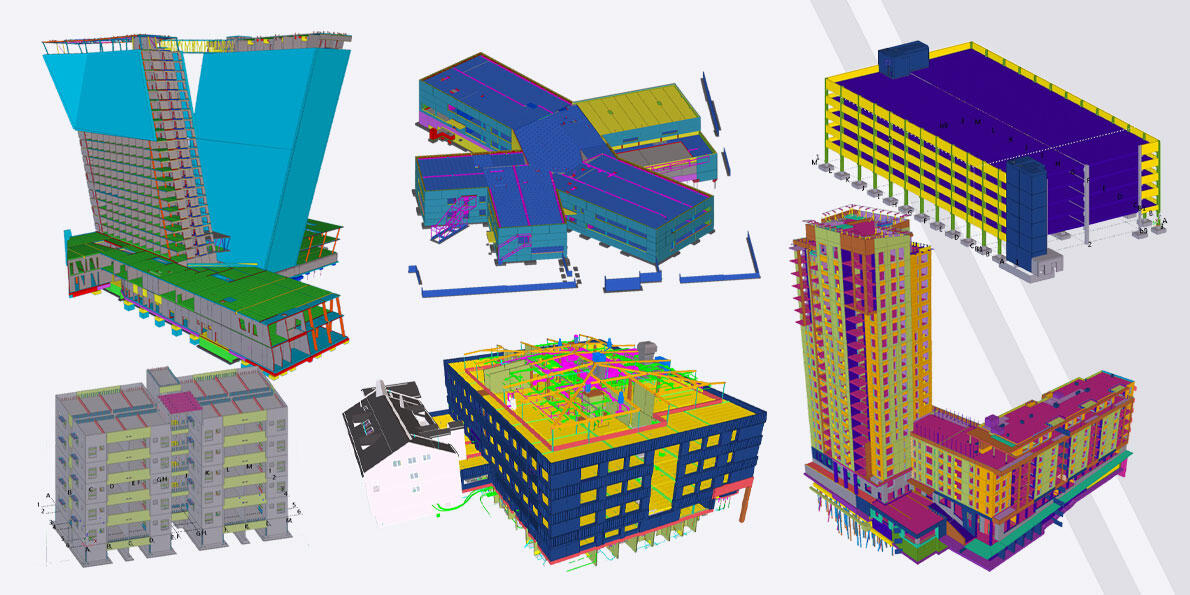

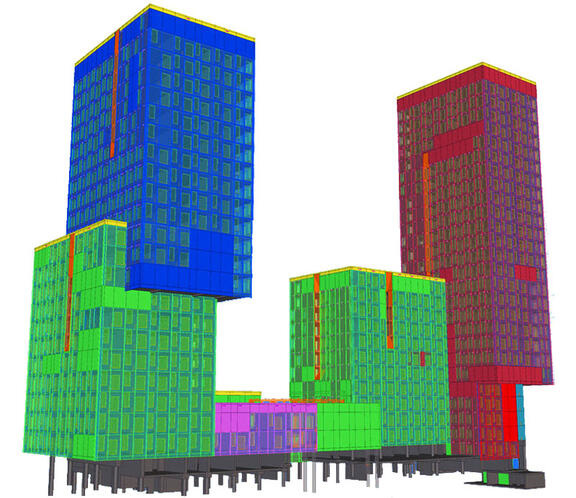

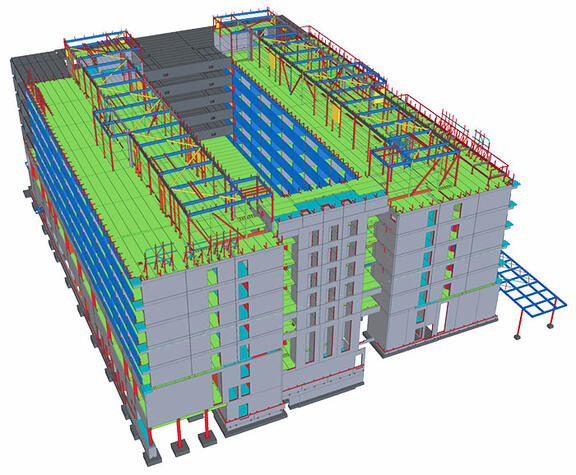

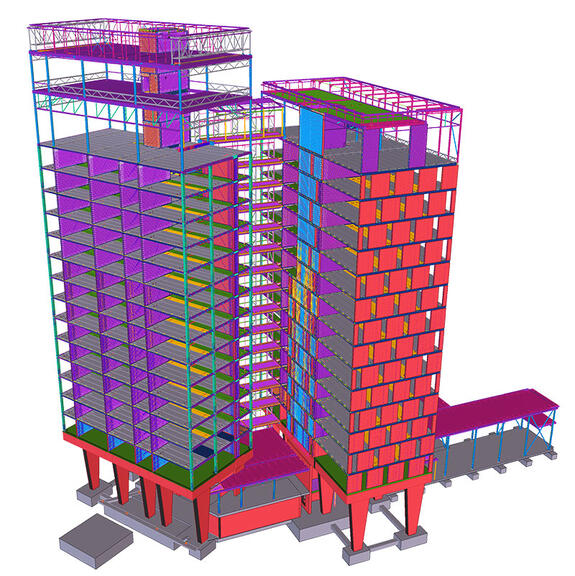

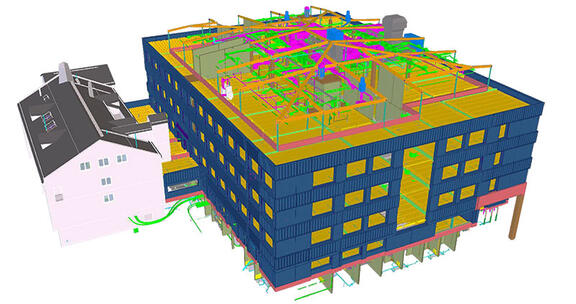

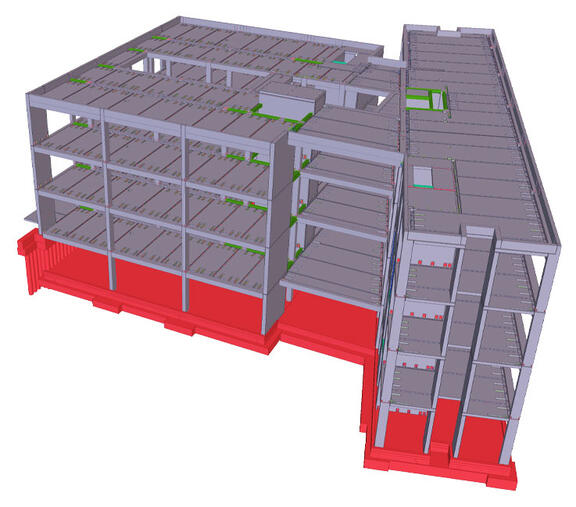

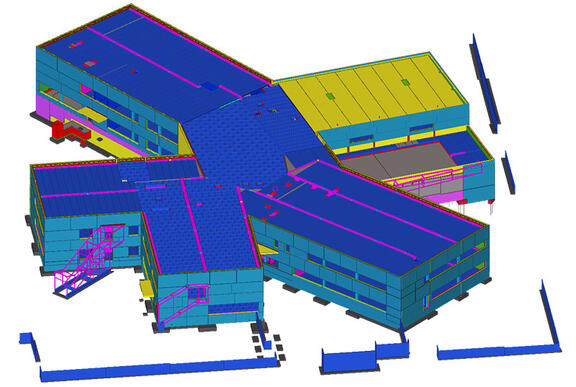

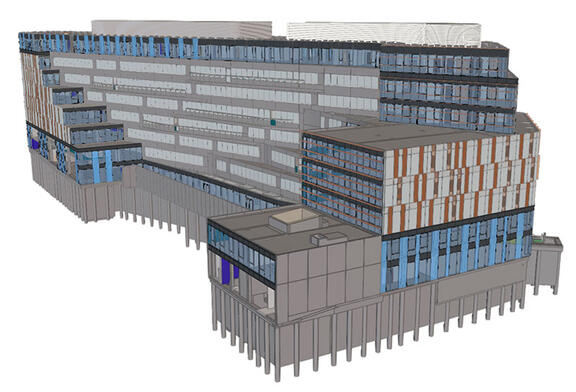

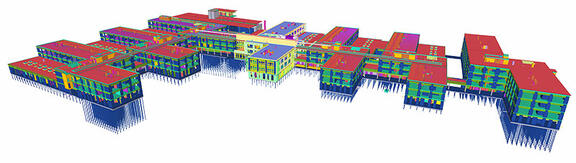

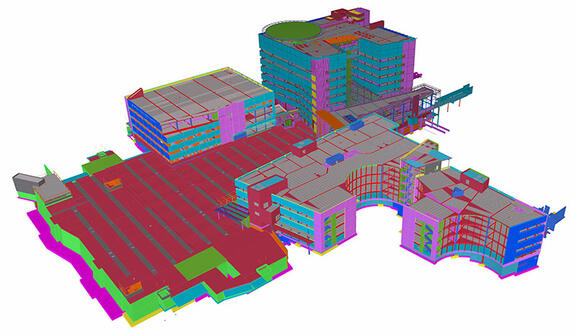

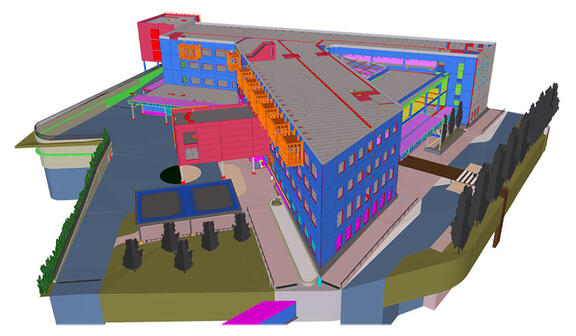

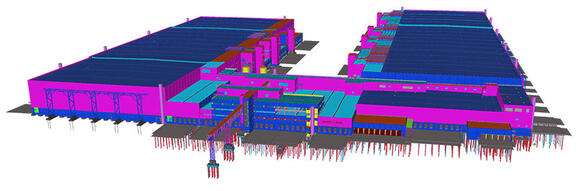

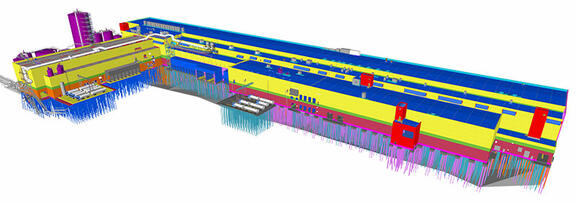

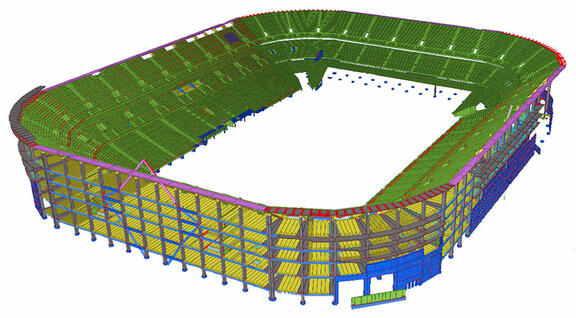

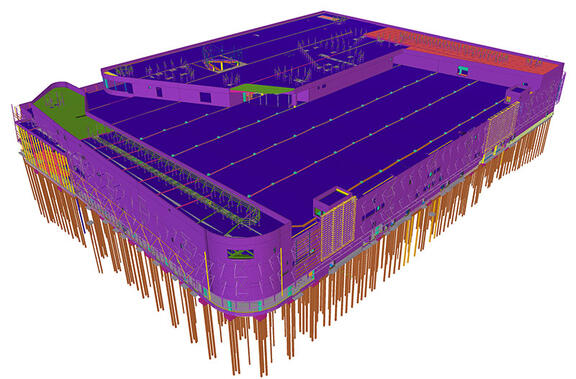

Any precast project

With Tekla Structures, you can create any type of structural precast project, whether it is commercial, public or industrial - even special structures. Here are examples of different kinds of projects from our customers

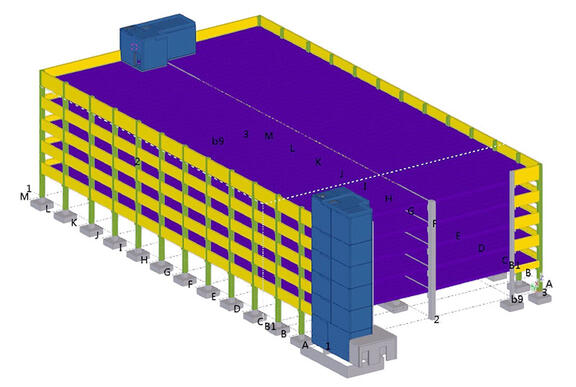

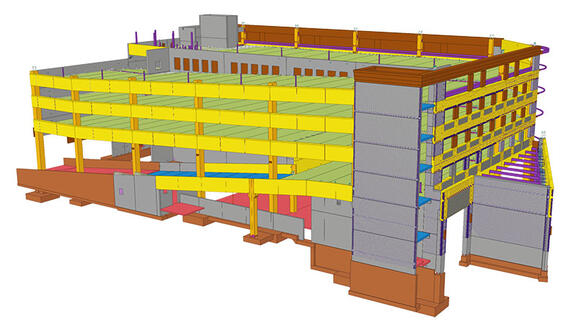

Parking structures

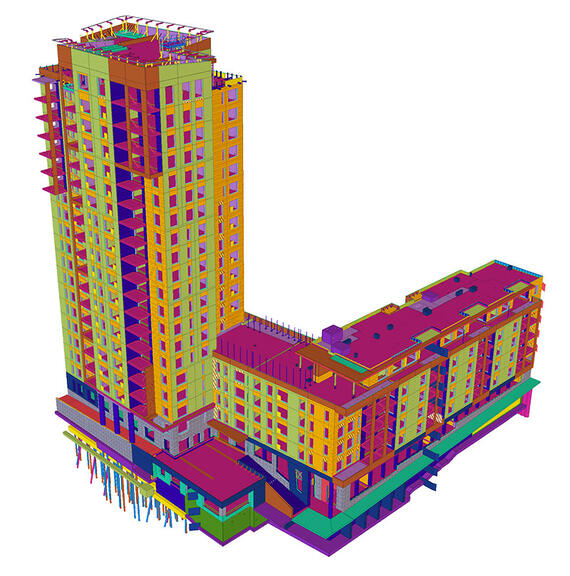

Residential towers

Residential low-rise / small housing

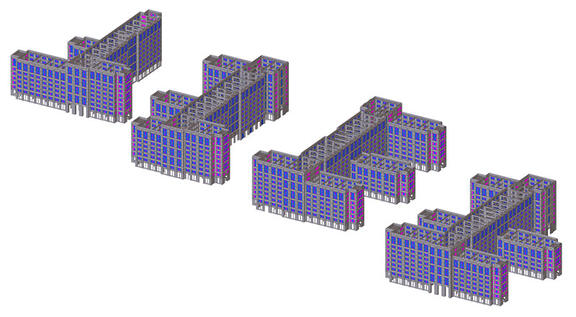

Student housing

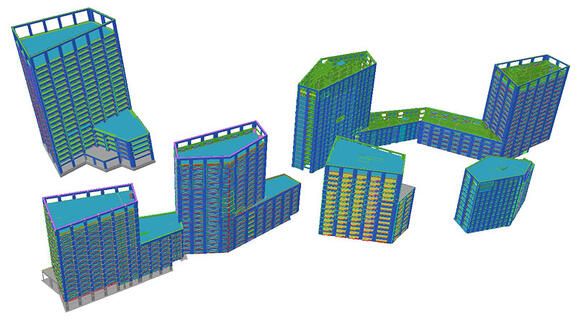

Urban development / Affordable housing

Hospitality / hotels

Educational facilities - schools and institutions

Offices

Health care facilities / hospitals

Warehouses / logistic centers

Industrial buildings

Stadiums and sports facilities

Shopping centers / hypermarkets

Bridges

Special projects / attractions

Infrastructure projects

With Tekla you can

- Create any structure, regardless of complexity or size - also multimaterial projects

- Reduce waste and total cost

- Estimate accurately and manage risk when bidding

- Avoid detailing and fabrication errors and minimize the need for rework

- Link with production machinery and transfer information efficiently

- Enhance communication and coordination using the model

IFC4precast

Modern model-based data exchange for precast industry

Overcoming the challenges of existing file formats, and disconnecting the factory constraints from detailing phase, IFC4precast is the future way of communicating the constructible model to manufacturing system based on IFC4 data format. The IFC4precast project, supported by the buildingSMART, aims at combining the best abilities of each existing precast fabrication format to create a modern process for collaboration that serves the needs of construction lifecycle and even beyond.

"In practise this means that IFC4 will be enriched with the characteristics of precast manufacturing, so that all relevant intelligence of the constructible model is readable for the manufacturing systems without flattening BIM," says Thorsten Hertel, Product Manager Precast Fabrication, Structures Division, who is the Trimble representative of the IFC4precast project group.

The IFC4precast project group consists of industry-leading technology providers - such as Trimble - and industry professionals.